BALE BOILERS

For farmers, rural businesses and local communities looking for cost-effective heating systems, straw-fired biomass boilers offer significant advantages. Straw is thermally efficient, and cheaper than all fossil fuels and other forms of biomass. It is readily available as a by-product of agriculture and requires minimal processing to be used as a fuel.

MetalERG has manufactured straw-fired boilers since 1993, refining its designs in response to customer demand. Its latest model, Bio-Eco-Matic, offers greater automation at every stage to further enhance both ease of use and financial savings.

EKOPAL RM

Straw and Other Biomass-Fired Boilers

These are low-temperature boilers, designed to work in an open system with a storage tank. The boilers have the biomass combustion (gasification) chamber, afterburner and a tube type heat exchanger.

The EKOPAL RM boiler is fitted with a high pressure fan with an air damper adjusted automatically and microprocessor-based control system, which controls the biomass combustion process according to optimal parameters.

EKOPAL RM

Container Mounted Boilers Fired with Straw & Other

Biomass

There is also the possibility to execute the EKOPAL RM boilers as container-mounted. No need to build an additional boiler room is an undoubted advantage of this solution. The appliance is free-standing and does not require permanent bonding with the base.

ECOPAL S

Air Heaters Fired with Straw & Other Biomass

Based on the straw-filled boilers, MetalERG has developed the design of a range of air heaters, which can heat air to 120 degrees Centigrade. The straw burning system is the same as in EKOPAL RM boilers, i.e. the countercurrent system. The range of air heaters includes 6 sizes of heaters with power from 1000 kW to 1000 kW, adapted to all kinds of bales of straw starting from the smallest cubes with dimensions of 80x40x40 cm through the round bales with a diameter of 120-810 cm, up to high density cuboids with dimensions of 250x120x80 cm.

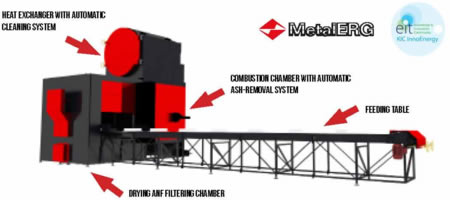

BIO-ECO-MATIC

Automatic Straw-Fired Boilers

Bio-Eco-Matic is the first fully automatic straw-fired batch boiler. The use of the system for automatic loading of the whole bales of straw along with a feeding chamber which is also a filter and dryer allows for significant improvement of the straw combustion process, which results in time and financial savings for the final customers.

It can be additionally fitted with an automatic ash removal system and heat-exchanger cleaning system to maximize the easiness of service. Bio-Eco-Matic was optimized in terms of both efficiency and low emissions. With the outputs from 500 KW to 2 MW it is an excellent solution for large agricultural farms, rural communities, as well as companies located in rural areas.

EXHAUST AFTER TREATMENT SYSTEM

Mini-Cyklon

The basic and easiest dust removal system used by MetalERG. This "collecting chamber" removed the largest fraction of particulate matter in the exhaust gas. It operated on a principle of a cyclone (centrifugal force), which causes the greater solids in the exhaust gas to be separated and fall to the ash reservoir and dedusted exhaust gas is directed to the stack. The efficiency is about 40% in the range of the largest fraction of particulate matter.

EXHAUST AFTER TREATMENT SYSTEM

Multicyclone

An extended, more advanced version of the collecting chamber. The system operates similarly to the collecting chamber using a centrifugal force. The device consists of a set of small collecting chambers, where the flowing exhaust gas reaches high peripheral speeds. Because the dimensions of individual "cyclones" are small, the system creates several or more small "cyclones." This design allows the achievement of much higher efficiency (up to 70%) and a much wider range of dust PM10 and PM2.5. This design causes that only clean (free of dust) exhaust gases are sucked in through the stack and the dust falls into the dust chamber.

EXHAUST AFTER TREATMENT SYSTEM

Electrostatic Precipitator

Electric precipitator is a kind of dust collector where dust removal from the flue gas occurs with the help of electrostatic forces acting on the particles of gas. Voltage usually used is at 30-80kV, which is very effective. In our system we use a dual exhaust gas cleaning system, thereby obtaining an overall efficiency of over 90%.

1614 County Highway 16

Burlington Flats, NY 13315

Tel: 607-643-6122 Call Us